- Hydraulic Seals

- Pneumatic Seals

- Rotary Shaft Seals

- Oil Seals

- O-Rings

- Gaskets

- Rubber Bushing

- Rubber Buffers

- Customized Parts

COS Technology supply a wide range of hydraulic seals in both light duty and heavy duty applications. This range includes rod seals, piston seals, wiper seals and guide rings. The range of seals can cope with:-

- Wide temperature fluctuations

- Irregular duty cycles and maintenance

- High lateral forces and deflections

- Very dirty conditions

- High system pressures and pressure peaks

Sealing components are used to retain the hydraulic medium securely inside a hydraulic system. A defined moistening of the counter surface with lubricating medium is desirable when the required service life is taken into account. A sealing component is referred to in this regard as leaky if the hydraulic medium is visible from the outside in the form of dripping leakage.

Pneumatic seals are any of a class of seals used in applications including rotary or reciprocating motions. They are often used in pneumatic cylinders and valves. Pneumatic seals do not work well under high pressure. Therefore, they are generally used in areas of lower pressure.

Pneumatic seals require minimal lubrication when exposed to air in order to create a tight seal. Pneumatic seals may also be exposed to high operating speeds at which the pressure is not high. Piston seals, rod seals, flange packings, u-cups, and vee-cups are a few sealing designs that take advantage of pneumatic seals. The difference between pneumatic seals and hydraulic seals is pressure. Pneumatic seals typically have a pressure range of 1 to 150 pound-force per square inch (psi), while hydraulic pressure can reach greater than 10,000 psi.

Sometimes, composite seals are used as pneumatic seals. Composite seals are seals composed of two or three different materials. Therefore, pneumatic seals are often found in products requiring one seal for many parts. A PTFE ring and an elastomer ring are often used in this situation. NASA uses this technology in their rocket systems. Composite pneumatic seals are also used in the diesel engines for trucks.

A pneumatic seal’s sealing orientation can be internal as with a rod seal, external as with a piston, symmetrical, or axial. With internal pneumatic seals, a housing bore surrounds the seal and the sealing lip touches the shaft. This seal requires very little lubricant.

With external piston pneumatic seals, the seal surrounds a shaft and the sealing lip touches the housing bore. This system requires more lubrication. Symmetric pneumatic seals are the same on both sides, and axial pneumatic seals fit axially against the housing. In both cases, however, the seals are used externally and require more lubrication.

Rotary applications need only one pneumatic seal. This seal is considered to be single acting because it can seal in one axial direction while the application is moving. On the other hand, a reciprocating application requires two pneumatic seals, or double acting seals. In this case, one seal is needed for each of the directions. Double acting pneumatic seals are more complicated than single acting ones.

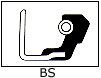

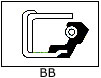

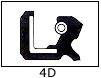

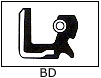

The ubiquitous rotary shaft seal is often taken for granted, however careful consideration of operating paramaters at the design stage can often lead to longer life and optimised performance.

Several features need to be factored into seal design:-

- Is an external static seal needed?

- Is a dust lip to prevent ingress of foreign matter required?

- What media are to be sealed?

- Are the seal and tension spring materials compatible with this media

- Circumferential speed

- Upper and lower temperature limits

- Will the seal be pressurised?

- Are there vibrations, or heavy loads?

- What shaft and housing sizes are readily available?

All of these factors affect seal choice, to ensure leak tightness, reliability, compatibility, low friction and easy fitting.

So whether you are designing a new transmission unit or repairing a gearbox, give us a call and we can take the guesswork out of your seal selection. E mail at sales@chinaoilseals.com

For really arduous applications we have a whole range cassette seals, which perform well, even in the most difficult environments

|

|

|||||

|

|

|||||

|

|

|||||

|

|

|||||

|

|

|||||

|

|

|||||

|

|

|||||

|

|

|||||

|

|

|||||

|

|

|||||

|

|

|||||

|

|

|||||

|

|

|||||

|

|

|||||

The O-ring is the most common type of fluid seal. An O-ring’s simple design lends itself to a multitude of sealing uses, including static, reciprocal, oscillating, and dynamic applications at low speed and pressure. In elevated operating pressure environments, addition of a backup ring will greatly increase the extrusion resistance of an O-ring.

The most basic shape of an O-ring is a simple circular sealing torus, usually made from an elastomeric material. Beyond the standard O-ring, All Seals can supply more advanced sealing designs such as Quad Rings, which are specially designed for low pressure sealing. All Seals also offers O-rings in advanced materials such as Viton®, Viton Extreme®, and Teflon®.

All Seals stocks over 200 million O-rings in 13,000 different size and material combinations.

COS offers virtually limitless gasket design possibilities. We utilize cutting edge technologies, including water jet cutting for intricate shapes and small production runs. We can supply a full range of quality gaskets in all shapes and sizes utilizing advanced materials designed specifically to offer our customers maximum durability.

For all of your gasket requirements, please contact us.

Gasket Types

|

|

W have a large selection of rubber bushings in our warehouse. A variety of the bushings we supply are custom made, and we are capable of attaining many other specifications that will meet your custom needs. If what we have does not satisfy you, contact us and we will do our best to find what you are looking for.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Being the leader in our domain we are able to manufacture and supply top notch quality of crane rubber buffers and industrial crane rubber buffers for the clients. These rubber buffers are superior in quality and performance and are widely used for various applications. We made the entire ranges by using superior quality materials such as natural rubber, Nitrile, neoprene, EPDM, and Viton. These heavy duty buffers are able to eliminate any type of noise, shock, vibration, impact and provide cushioning to various machines and this makes our products high in demand in the market. For the quality assurances the entire ranges are tested on different parameters to avoid the manufacturing defects. Moreover our rubber buffers are equipped with high degree of torrential stiffness, Wear and tear free, Resistance to oxidation, ozone and radiation, indefinite shelf life, Anti abrasive and this makes our products a preferred choice among our clients. We make the entire ranges accessible at cost effective prices.

| COS can fulfill all your molded and extruded needs whether they be transfer, injection (LIM) or compression molded from any type of elastomer. COS can also produce rubber-to-metal bonded products as well as extruded sponge rubber or homogeneous profiles. Products can be supplied in all types of elastomers. If you need assistance in choosing a material please contact us for assistance or select on a material below for product data and available general compounds. Should one of these compounds not meet your requirements please let us know. There are hundreds of various formulations and impossible to list every option.Markets Industries: Automotive, Medical, Electronics, Power Generation, Valve & Pump, Propane & LPG. |

Contact us for additional information.